Machines of Industrial Drying Systems

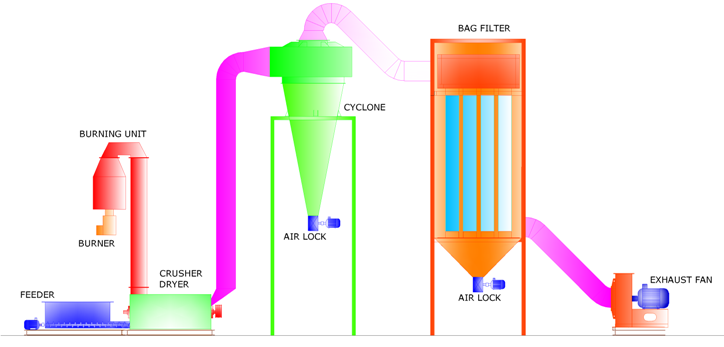

PNEUMATIC DRYER One of the most widely used drying systems is pneumatic drying and is also known as flash drying.The large surface area for heat and mass transfer and the high convective heat and mass transfer coefficients, which take place at these units, result in high drying rates and as a result, high drying capacity. The size of particulates to be dried is usually in the range of 10–500 mm. One of the features of these types of dryers is the relatively short contact time between the hot air and the particulate materials (0.5–60 s) at the drying section. Because of this the material temperature stays always low in the drying process.The simple flash drying system includes seven basic components: the heater, the wet material feeder, the dryer and crusher, the cyclone, the jet filter and a exhaust fan.

To get more information you can watch videos below

EQUIPMENTS OF PNEUMATIC DRYERWET MATERIAL FEEDER

Screw: Diameter is determined by capacity. Spiral stainless steel drying of food products.Feeder Motor: Specially selected by the size of the machine.Speed Control Device: To control the feeding capacity by using control board.CRUSHER

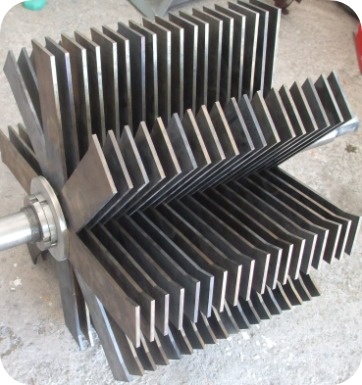

Function: The product mixing and more rapid drying process was made by crushers. Crushers and crushing on the mixing blades are specially designed product.Mixing Blades: carbon steel sheet laser will be produced as predicted. Food products can be manufactured in stainless steel material.Shaft: I can be can be made for the stainless steel material for food products.Rotary Motor: specially selected by the size of the machine.Extras: The Crusher adjustment system will be balanced.DRYING CABINET |

| Products | Products |

| Irish Potato Starch | Manganese Dioxide |

| Rubber Chloride | Potassium Bicarbonate |

| Ammonium Chloride | B.H.C. |

| Magnesium Hydroxide | Powerful Bleaching Powder |

| Sugar | Clay |

| Coal | P.V.C. |

| Potassium Chloride | Fish Powder |

| Dicyandiamide | White Lead |

| Clay for Tiles | Melamine |

| Sweet Potato Starch | Gypsum |

| Diatom Earth | Wheat Starch |

| Fire Clay Materials | Medicines |

| Bean Curd Refuse | Fish Meal |

| D.A.P. | Benzol Peroxide |

| White Kaolin | Silica Powder |

| A.B.S. Resin | Silica Terra Alba |

| Clay & Sand | Rayon Sulphate of Soda |

| Ammonium Phosphate | Ammonium Sulphate |

| Vinyl Chloride | Rubber Lignin |

| Calcium Carbonate | Vinyliden Chloride |

| Polycarbonate | Sodium Sulphate |

| Polypropylene | Calcium Formate |

| Terra Alba | Copolymer |

| Sodium Bicarbonate | Synthetic Resin |

| Polyethylene | Nissil |

| Sodium Cyanide | Activated Terra Alba |

| Acrylic Resin | Powder Extinguisher |

| Rubber Aging Preventive | Chemicals |

| Chrome Ore | Flour |

| Baking Powder | Sulphate of Soda |

| Glutem | Polypropylene |

| By-product Sulphate Ammonia | Potassium Nitrate |

| Rayon Sulphate of Soda. | Corn Skin |